OceanGlide

Alfa Laval OceanGlide is a unique air lubrication system based on fluidic technology. By producing an even layer of micro air bubbles across the flat bottom of the vessel, OceanGlide minimizes friction between the hull and the surrounding water. This reduction in drag means that less fuel is burned, which is less money spent and less CO2 emitted into the atmosphere. Likewise, it reduces marine noise. Together, these factors make OceanGlide an important step towards more sustainable shipping.

A smooth path to real savings

- Fuel savings of up to 12% mean reduced CO2 and improved EEDI, EEXI and CII

- Fluidic technology produces an even layer of micro bubbles with few compressors

- Coverage of the entire flat bottom area maximizes drag reduction

- Individually controlled sections allow full optimization of the air layer

- Easy newbuild or retrofit installation – no large sea chests or compressor placement requirements

Alfa Laval’s patented OceanGlide technology delivers on the promise of air lubrication. Using fluidic oscillators, it generates an even layer of micro air bubbles across a vessel’s entire flat bottom area. The system produces 240,000 bubbles per second and metre, which reduces specific drag by up to 75%. This enables proven savings of up to 12%, with a short payback time of just 2–3 years.

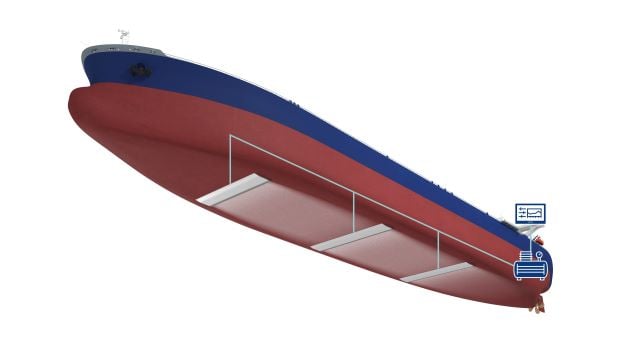

Installed in low-profile bands across the bottom of the vessel, the OceanGlide system needs few compressors and involves only small hull penetrations. Since there are no sea chests or other large vessel modifications, it can be installed at any shipyard and on any vessel – new or existing.

How fluidic air lubrication works

Alfa Laval OceanGlide is unique in combining air lubrication with fluidics – the control of fluid pressure and flow by means of precisely shaped channels, without any moving parts. This patented integration means OceanGlide needs no sea chests or large hull penetrations, and it produces the air layer with unmatched efficiency.

OceanGlide divides the vessel’s flat bottom into sections, each with its own air distribution band. At the rear of each band is a row of fluidic oscillators, which are the individual air distribution units. Through fluidics, the oscillators produce tiny, uniform bubbles using very little compressor power. Since the bubbles coalesce almost instantly when leaving the oscillator, they create an even and homogenous air layer.

Air distribution bands offer the best possible setup for reducing friction in real-life conditions. With their hydrodynamic, wing-shaped profile, the bands add almost no drag when the air lubrication system is switched off. More importantly, each band can be steered independently, which allows optimization of the air layer by section. Together with the reduced number of compressors needed (1–3 on average), this maximizes the energy efficiency and propulsion power savings achieved with OceanGlide.

OceanGlide – proof in operation

Tharsis Sea-River Shipping was the first to install Alfa Laval OceanGlide. On the coaster M/V Tharsis, the technology has achieved up to 10% fuel savings. The company sees fluidic air lubrication is as a key technology on its path to more sustainable shipping.

A breakthrough in maritime efficiency

Fluidic air lubrication is a new innovation that reduces propulsion power needs by up to 12%, providing payback through reduced fuel consumption. It was successfully installed on the coaster M/V Tharsis in just one week, improving efficiency with no impact on maneuverability or stability.