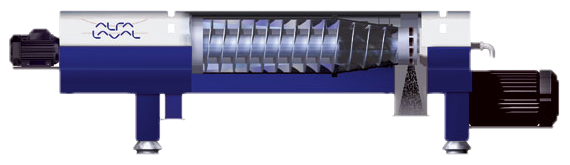

P3

Alfa Laval P3 decanter centrifuges help eliminate many of the problems associated with tailings dam operations and filtration technologies. They are a proven and effective dewatering solution for slimes, clays and silts and other fine tailings. The special deep-pond design, the unique conveyor and the optimized cone angle enable you to treat volumes. The resultant spadeable cake can be disposed of by co-disposal or dry stacking while the separated water can be recycled for reuse.

Built to last with highest throughput on the market

- Able to dewater ultrafine material < 10 micron in continuous operation

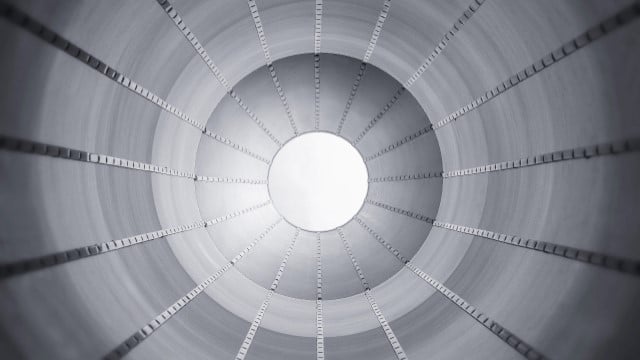

- Robust design (fully wear protected) for high reliability

- No filter cloth, limited quantity of wash-water at shutdown

- Low capital and installation cost

- Can be trialled on a pilot for proof of concept and then scaled up

How it works

Learn more

Read more about the efficiency, practicality and technical details of the Alfa Laval P3 solid-bowl decanter centrifuge by downloading the leaflet.

Customer stories

Read how our P3 decanters have revolutionized tailings management in various environments

Rix’s Creek Coal Preparation Plant, Australia

Alfa Laval decanter centrifuge has provided an alternate method of coal tailings management at Rix’s Creek and delivered significant savings in capital expenditures , water consumption and energy usage.

Mature fine tailings, Canada

More than 30 Alfa Laval decanter centrifuges have been installed at three different tailings treatment sites in Canada. The decanters have proven to be an outstandingly efficient solution for large-scale dewatering of tailings. With their large capacity, high efficiency and reliability, Alfa Laval decanter centrifuges have set a new standard for tailings treatment.

Eti Maden, Turkey

The world’s largest borate mining company, Eti Maden in Turkey, uses an array of fully protected Alfa Laval decanter centrifuges to separate tailings from a saturated borate solution. The company is very pleased with the long track record of reliable operation, low maintenance costs and strong local service support from Alfa Laval.

Ask the experts!

If you are looking for ways to increase the efficiency of your tailings management and make a meaningful contribution to the global sustainable development goals, contact Alfa Laval today to learn more about our proven and cost efficient solutions.