Customer references for Alfa Laval spiral heat exchangers

Refinery

Alfa Laval heat exchangers help boost capacity in bio-refinery

SunPine AB Sweden increased capacity and reduced maintenance needs in its bio-refinery in Piteå, Sweden by installing Alfa Laval spiral and Compabloc heat exchangers. Close cooperation between SunPine and Alfa Laval was an important part of the successful execution of this project.

How 8 spiral heat exchangers saved €1,647,000 a year

High cost of maintenance for the heat exchangers used in the visbreaking process at a newly acquired refinery plant in Russia was a key concern. Alfa Laval was asked to prove that their spiral heat exchangers could solve the problem and delivered that proof – along with some impressive savings.

Spiral heat exchanger solves costly fouling problems

A major US refinery was experiencing severe fouling and plugging problems in two shell-and-tube heat exchangers installed to cool desalter effluent using cooling water. When replacing them with a fouling-resistant spiral heat exchanger the result exceeded expectations.

The ultimate solution to fouling problems

Leuna Germany’s MIDER refinery, owned by Total S.A., originally installed two tubular heat exchangers for cooling bottoms product in their fluid catalytic cracking unit. When replaced with spiral heat exchangers, down-time and maintenance cost were drastically reduced.

Chemicals

Capacity boost by 30% and emission cuts by 80%

Retrofitting the Remat Chemie vacuum film evaporators with special double-pass Alfa Laval Compabloc heat exchangers and one spiral heat exchanger as a preheater boosts capacity and reduces emissions.

Frequent cleaning a thing of the past

Mexichem, a global leader in plastic piping systems and in the chemical/petrochemical industries, needed to increase its production capacity to meet market demands. As an added bonus the extra heat recovered by the new heat exchangers resulted in annual steam savings of 110,000 euros.

Hot and cold water for free

A mid-sized styrene butadiene rubber producer in Asia installed two Alfa Laval spiral heat exchangers and one Compabloc to recover waste heat from a stripping column. The heat is now reused in the plant and annual energy costs are estimated to be about 660,000 euros lower as a result.

Other industries

Coke oven gas

Base minerals and mining

Energy savings and reduced emissions at coke plant

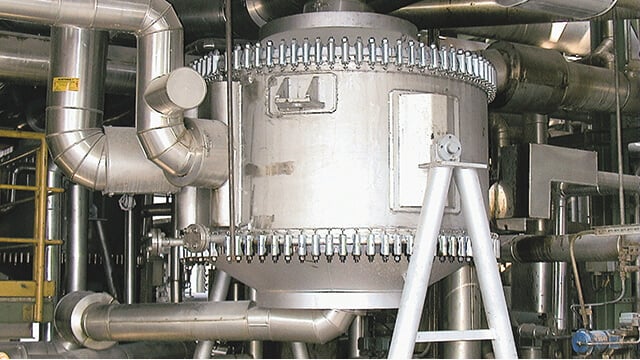

To comply with European emission and process regulations for the coke industry, Avdeevskiy coke processing works in Ukraine replaced two open final gas cooling systems, using scrubbers, with Alfa Laval closed systems utilizing 11.5 metre high spiral heat exchangers in its plant.

One of the world's largest zinc producers

"We use these units because they’re very strong and very easy to clean and of course because the thermal efficiency is high." - Francisco Tarmago, Technology Manager, Asturiana de Zinc