Aalborg Micro

The Alfa Laval Aalborg Micro is a uniquely compact boiler/economizer designed for waste heat recovery from a vessel’s auxiliary engines. On land the Aalborg Micro function as a compact exhaust gas heat exchanger/steam generator, designed for waste heat recovery from gas/MDO/HFO engines and gas turbines.

Application

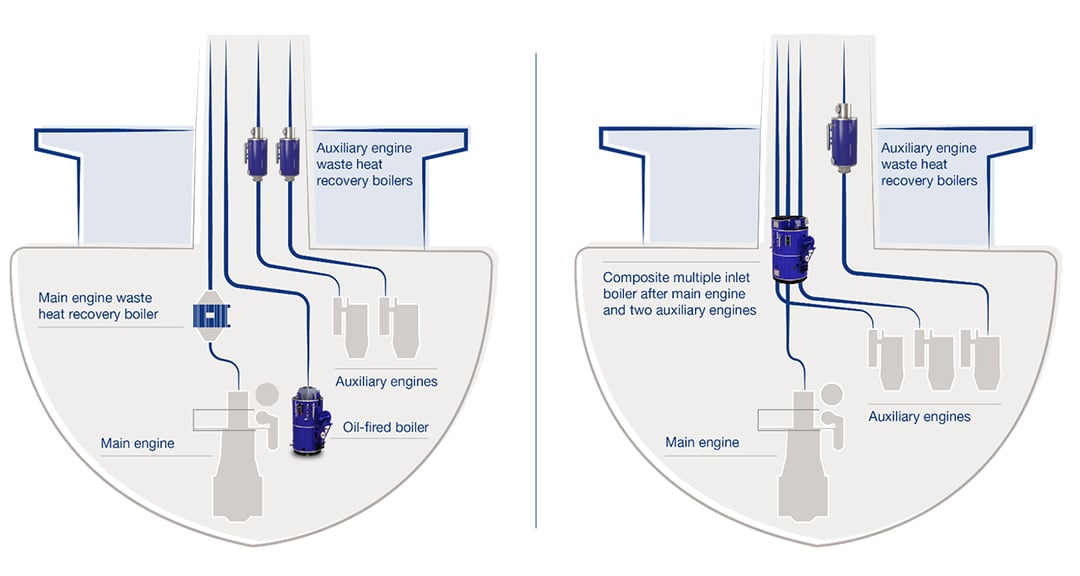

Only a portion of the fuel energy released by marine engines actually goes to propulsion. A large amount of it escapes as heat, and it makes sense to reclaim as much of this energy as possible. This is true not only for main engines, but for auxiliary engines as well.

Steam produced with the Aalborg Micro can support or fulfil steam needs in port, but it can also serve other functions. For vessels whose long-stroke main engines produce cooler exhaust, it can provide a needed steam boost during a voyage. Vessels that use blended fuels from 2020 onwards may also require additional steam, since these fuels will need to be stored at a higher ambient temperature – even if their pumping temperature is lower.

Configuration examples

Land

The Aalborg Micro is a compact exhaust gas heat exchanger especially designed for waste heat recovery from small gas turbines as well as from small engines & clean process flue gas. Furthermore, it is also unique when used as an economizer/condensing economizer e.g. for gas or diesel fired boilers.

Applications

The Aalborg Micro can operate with a diversity of media, including water, steam, triethylene glycol (TEG) and thermal fluid oil (TFO). To date, Alfa Laval Aalborg Micro heat

exchangers have been used in different applications across a wide range of industries.

Design

The Aalborg Micro is build in a durable design featuring a heating surface consisting of a number of coaxial tubes arranged in a vertical or horizontal cylindrical shell plate. This, ensures a long-term, trouble-free performance and offers capacities ranging from approximately 250-5000 kW.

The heating surface of the Aalborg Micro has been developed for easy maintenance. Cleaning can be performed either with a pyrolysis process when operating in dry-run mode or using optional soot blower rings with compressed air, steam or water.

When necessary, an integrated regulation damper allows a part of the exhaust gas to bypass the unit’s heating surface.